RIMAH AL-SHRQ FIBERGLASS TANKS AND RESERVOIRS MANUFACTURING LLC

Menu

Menu

Innovative Technologies Driving Durability & Performance

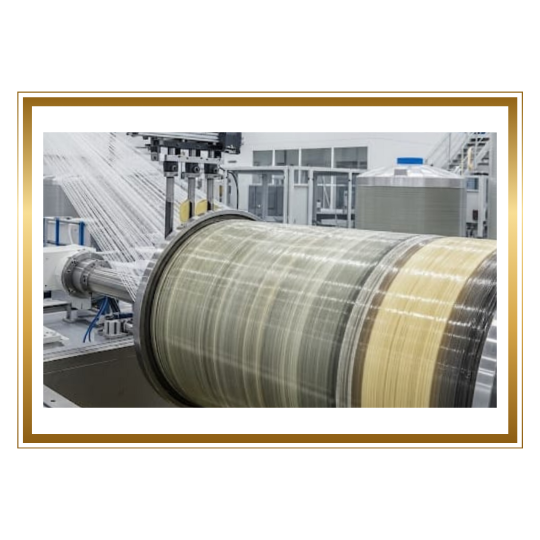

Automated machines wrap fiberglass filaments soaked in resin around a mandrel. This ensures high strength, uniform thickness, and excellent structural integrity.

Glass fiber mats are manually layered and saturated with resin for durability. Spray-up combines chopped fibers and resin, ideal for custom, low-volume shapes.

Fiberglass and resin are compressed under heat in precision steel molds. This method produces smooth, accurate panels with consistent dimensional quality.

Computer-guided plasma systems cut and shape steel with extreme precision. Accurate cuts ensure perfect fit before glass enamel lining applications.

Protective linings like epoxy and polyurethane prevent chemical damage. They ensure hygiene, safety, and long-lasting structural performance.

Steel plates are coated with glass powder and baked at 850°C. This process creates a corrosion-resistant and chemically inert surface.

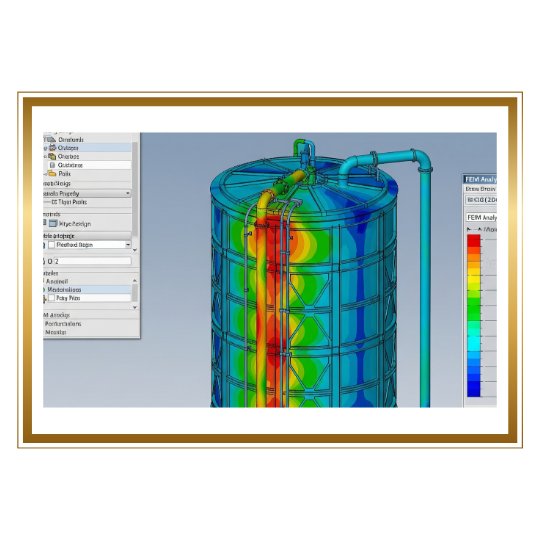

3D CAD and FEM simulate stress, pressure, and environmental factors for accurate design. This guarantees optimal performance, superior safety, and long-term reliability in all conditions.

We use resins like vinyl ester and epoxy that meet global standards. These offer superior chemical resistance, UV stability, and durability.

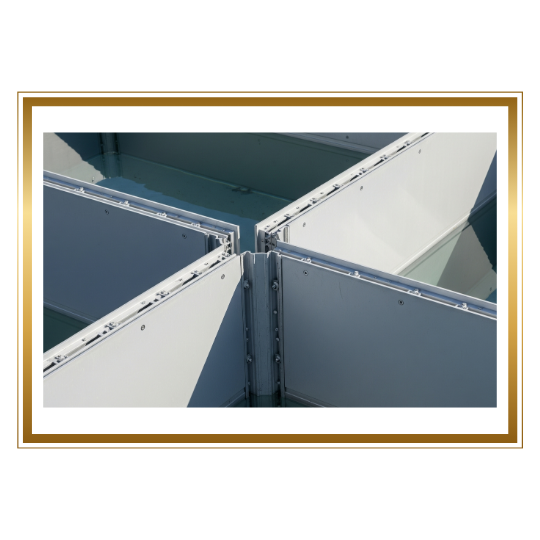

Pre-fabricated panels allow easy transport and fast on-site assembly. This system ensures scalability, flexibility, and cost-effectiveness.

Hydrostatic, vacuum, and ultrasonic tests ensure leak-proof reliability. Every tank is verified for safety before and after installation.

Email:

info@rimahreservo.com

Contact Numbers:

UAE: +971 542459914 | +971 551690524

KSA: +966 545159249

© 2025 Rimah Reservo. All rights reserved.